Ethyl Acetate Supply Polyurethane (PU) CAS 51852-81-4 China Best Price – Chemwin Detail:

Product Name:polyurethane

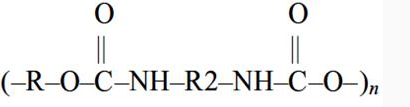

Product molecular structure:

Chemical Properties:

Polyurethanes were first produced and investigated by Dr. Otto Bayer in 1937. Polyurethane is a polymer in which the repeating unit contains a urethane moiety. Urethanes are derivatives of carbamic acids that exist only in the form of their esters[15]. The major advantage of PU is that the chain is not composed exclusively of carbon atoms but rather of heteroatoms, oxygen, carbon and nitrogen[4]. For industrial applications, a polyhydroxyl compound can be used. Similarly, poly-functional nitrogen compounds can be used at the amide linkages. By changing and varying the polyhydroxyl and polyfunctional nitrogen compounds, different PUs can be synthesized[15]. Polyester or polyether resins containing hydroxyl groups are used to produce polyesteror polyether-PU, respectively[6]. Variations in the number of substitutions and the spacing between and within branch chains produce PUs ranging from linear to branched and 9exible to rigid. Linear PUs is used for the manufacture of fibers and molding[6]. Flexible PUs is used in the production of binding agents and coatings[5]. Flexible and rigid foamed plastics, which make up the majority of PUs produced, can be found in various forms in industry[7]. Using low molecular mass prepolymers, various block copolymers can be produced. The terminal hydroxyl group allows for alternating blocks, called segments, to be inserted into the PU chain. Variation in these segments results in varying degrees of tensile strength and elasticity. Blocks providing rigid crystalline phase and containing the chain extender are referred to as hard segments[7]. Those yielding an amorphous rubbery phase and containing the polyester/polyether are called soft segments. Commercially, these block polymers are known as segmented Pus

Application:

Polyurethanes are one of the most versatile materials in the world today. Their many uses range from flexible foam in upholstered furniture, to rigid foam as insulation in walls, roofs and appliances to thermoplastic polyurethane used in medical devices and footwear, to coatings, adhesives, sealants and elastomers used on floors and automotive interiors[17,18]. Polyurethanes have increasingly been used during the past thirty years in a variety of applications due to their comfort, cost benefits, energy savings and potential environmental soundness. What are some of the factors that make polyurethanes so desirable? Polyurethane durability contributes significantly to the long lifetimes of many products. The extensions of product life cycle and resource conservation are important environmental considerations that often favor the selection of polyurethanes[19-21]. Polyurethanes (PUs) represent an important class of thermoplastic and thermoset polymers as their mechanical, thermal, and chemical properties can be tailored by the reaction of various polyols and poly-isocyanates.

Product detail pictures:

Related Product Guide:

We've been convinced that with joint efforts, the enterprise between us will bring us mutual benefits. We are able to assure you product or service quality and aggressive cost for Ethyl Acetate Supply Polyurethane (PU) CAS 51852-81-4 China Best Price – Chemwin , The product will supply to all over the world, such as: UK, Swansea, Wellington, Our professional engineering group will always be ready to serve you for consultation and feedback. We are able to also offer you with absolutely free samples to meet your requirements. Finest efforts will likely be produced to give you the ideal service and goods. For anyone who is thinking about our company and merchandise, please contact us by sending us emails or contact us quickly. As a way to know our merchandise and firm. lot more, you can come to our factory to find out it. We'll always welcome guests from all over the world to our business to build company relations with us. Please feel free to get in touch with us for business and we believe we are going to share the top trading practical experience with all our merchants.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top