China Polyurethane Acrylonitrile Butadiene Styrene Copolymers (ABS) CAS 9003-56-9 China Best Price – Chemwin Detail:

Product Name:ABS resin

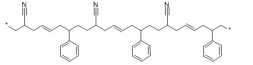

Molecular format:C45H5N3X2

CAS No:9003-56-9

Product molecular structure:

Chemical Properties:

ABS (acrylonitrile-butadiene-styrene terpolymer) is an amorphous engineering thermoplastic material that provides a good balance of toughness and rigidity. Each component of the terpolymer contributes specific features to the overall performance of this material. The styrene component provides gloss and rigidity while the butadiene component provides excellent impact properties. The acrylonitrile component contributes to melt strength and chemical resistance. ABS is resistant to attach to both mineral acids and bases. ABS is also resistant to both vegetable and mineral oils. ABS holds up well to most household cleaners.

Acrylonitrile-butadiene-styrene is available in both injection molding and extrusion grades. Additionally, ABS is easy to process. Compounding technology allows a wide variety of colorants to be compounded into ABS. This allows production in a wide range of custom colors. Applications for ABS products can be extended by the addition of additives such as stabilizers, flame retardants, and reinforcing fillers.

Application:

ABS’s light weight and ability to be injection molded and extruded make it useful in manufacturing products such as drain-waste-vent (DWV) pipe systems. Musical instruments such as recorders, plastic oboes and clarinets, piano movements, and keyboard keycaps are commonly made out of ABS.Other uses include golf club heads (because of its good shock absorbance), automotive trim components, automotive bumper bars, binoculars, inhalers, monoculars, nebulizers,non-absorbable sutures, tendon prostheses, drug-delivery systems tracheal tubes,enclosures for electrical and electronic assemblies (such as computer cases), protective headgear, whitewater canoes, buffer edging for furniture and joinery panels, luggage and protective carrying cases, pen housing, and small kitchen appliances. Toys, including LEGO and Kre-O bricks, are a common application.Household and consumer goods comprise the major applications of ABS. ABS plastic ground down to an average diameter of less than 1 micrometer is used as the colorant in some tattoo inks.When extruded into a filament, ABS plastic is a common material used in 3D printers.When it is used as a filament for the 3D printing by fused deposition modeling, it is suitable due to the high stability and various post-processing options (sanding, painting, gluing, filling), especially for the production of prototypes. Particular forms of ABS filaments are ABS-ESD (electrostatic discharge) and ABS-FR (fire resistant), which are used in particular for the production of electrostatically sensitive components and refractory prefabricated parts.

Product detail pictures:

Related Product Guide:

We emphasize enhancement and introduce new solutions into the market just about every year for China Polyurethane Acrylonitrile Butadiene Styrene Copolymers (ABS) CAS 9003-56-9 China Best Price – Chemwin , The product will supply to all over the world, such as: Bogota, Latvia, moldova, We only supply quality items and we believe this is the only way to keep business continue. We can supply custom service too such as Logo, custom size, or custom merchandise etc that can according to customer's requirement.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top