Best quality Phenol Latest Price - Polymethylmethacrylate (PMMA) CAS 9011-14-7 Factory Direct Supply – Chemwin Detail:

Product Name:POLY METHYL METHACRYLATE

Molecular format:C33H54O6

CAS No:3319-31-1

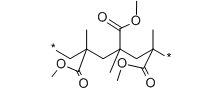

Product molecular structure:

Chemical Properties:

PMMA is an economical alternative to polycarbonate (PC) when tensile strength, flexural strength, transparency, polishability, and UV tolerance are more important than impact strength, chemical resistance, and heat resistance.[6] Additionally, PMMA does not contain the potentially harmful bisphenol-A subunits found in polycarbonate and is a far better choice for laser cutting. It is often preferred because of its moderate properties, easy handling and processing, and low cost. Non-modified PMMA behaves in a brittle manner when under load, especially under an impact force, and is more prone to scratching than conventional inorganic glass, but modified PMMA is sometimes able to achieve high scratch and impact resistance.

Application:

Acrylic prosthetic construction Artificial teeth Artistic and aesthetic uses PMMA, in the commercial form Technovit 7200 is used vastly in the medical field. It is used for plastic histology, electron microscopy, as well as many more uses. PMMA has been used to create ultra-white opaque membranes that are flexible and switch appearance to transparent when wet.[50] Acrylic is used in tanning beds as the transparent surface that separates the occupant from the tanning bulbs while tanning. The type of acrylic used in tanning beds is most often formulated from a special type of polymethyl methacrylate, a compound that allows the passage of ultraviolet rays. Sheets of PMMA are commonly used in the sign industry to make flat cut out letters in thicknesses typically varying from 3 to 25 millimeters (0.1 to 1.0 in). These letters may be used alone to represent a company’s name and/or logo, or they may be a component of illuminated channel letters. Acrylic is also used extensively throughout the sign industry as a component of wall signs where it may be a backplate, painted on the surface or the backside, a faceplate with additional raised lettering or even photographic images printed directly to it, or a spacer to separate sign components. PMMA was used in Laserdisc optical media.[51] (CDs and DVDs use both acrylic and polycarbonate for impact resistance). It is used as a light guide for the backlights in TFT-LCDs.[citation needed] Plastic optical fiber used for short-distance communication is made from PMMA, and perfluorinated PMMA, clad with fluorinated PMMA, in situations where its flexibility and cheaper installation costs outweigh its poor heat tolerance and higher attenuation over glass fiber. PMMA, in a purified form, is used as the matrix in laser dye-doped organic solid-state gain media for tunable solid state dye lasers.[52] In semiconductor research and industry, PMMA aids as a resist in the electron beam lithography process. A solution consisting of the polymer in a solvent is used to spin coat sil

Product detail pictures:

Related Product Guide:

We provide fantastic energy in top quality and advancement,merchandising,gross sales and marketing and operation for Best quality Phenol Latest Price - Polymethylmethacrylate (PMMA) CAS 9011-14-7 Factory Direct Supply – Chemwin , The product will supply to all over the world, such as: Kenya, British, Lithuania, We're introduced as a one of the growing manufacture supplier and export of our merchandise. Now we have a team of dedicated trained experienced who take care the quality and timely supply. If you are looking for Good Quality at a good price and timely delivery. Do contact us.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top